FORWARD-LOOKING

SUSTAINABLE

EFFICIENT

Your pontential

savings

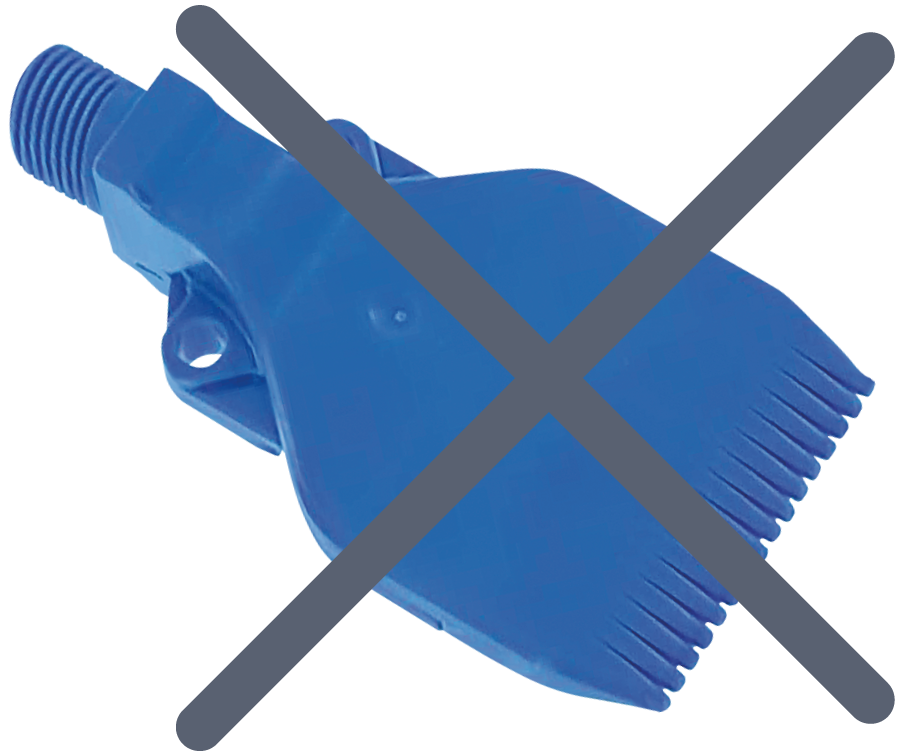

An incredible number of companies still misuse their existing compressed air system for continuous blowoff applications. This approach is highly questionable in terms of energy and extremely cost-intensive. Due to the lower initial costs, numerous companies are often tempted to use the simplest compressed air nozzles or their own constructions. The resulting operating costs exceed those of a decentralized solution many times over:

- Our systems achieve up to 90% energy savings compared to conventional compressed air solutions.

- The one-time purchase costs are amortized within a very short amount of time with simultaneously better drying results.

- No costs through hidden leakages

- Reduced maintenance costs thanks to long service intervals

- Low spare parts requirement

After an on-site assessment, we off er you internal feasibility analyses and practical application simulations in our technical center. We always aim for the best possible results based on the lowest possible energy consumption. With our systems you invest in your future.

REFERENCE PLANT | FELIX AUSTRIA

Saving of 100,000 kW per system

Example

Supply by compressed air network

4 x multi-channel nozzles 48mm

Energy costs per year

in 3-shift operation:

€ 13,680,-

excl. maintenance costs

With intelligent

GESETE blower technology

4 x stainless steel flat jet nozzle

Energy costs per year

in 3-shift operation:

€ 760,-

incl. maintenance costs and spare parts costs

Your saving

€ 12,920,-

(Example calculated with electricity costs of € 0.15/kWh)

„Due to permanently increasing energy costs, a conscious use of energy is inevitable nowadays. With our complete systems, we off er our customers the opportunity to save up to 90% of their energy costs and to simultaneously improve drying results in the smallest of spaces.“

Martin Werfring, CEO | GESETE GmbH

We care about your energy

Do you have questions or would you like to find out more?