FOOD INDUSTRY

INDUSTRIES

Drying solutions specifically adapted to your hygiene and quality standards

The dynamics in the food industry are significantly faster than in many other industrial sectors. As a manufacturer, you have to react flexibly to changing demands from the market, customers and competitors and the notice is getting shorter and shorter. Especially in the field of hygiene, there’s no room for compromise. Quality and efficiency often provide a huge advantage in the face of increasing competition.

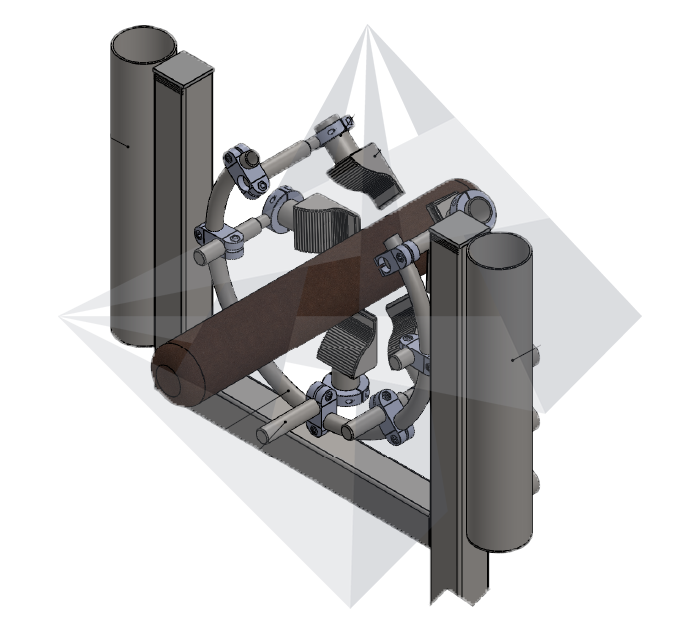

FLEX | line

Flexible and universally applicable

99,995%

Filter class HEPA H14 can be selected (germ-free air)

Energy

Up to 90% energy saving (compressed air)

Shortest design

Smallest footprint on the market

BELOW 80 dBa

Quieter than comparable systems

Open products

BURGER BUNS

Industry: Baked goods

Application: Removal of residues

After the buns are baked, remove them from the baking trays. Afterwards, these trays have to be cleared of sesame seeds and crumbs so as not to contaminate the underside of the products in the next filling process. For this, we offer cost-efficient removal of topping residues.

BURGER PATTIES

Industry: Meat products

Application: Clean, germ-free air

After being removed from the freezer, a GESETE system was installed to blow off ice crystals that stuck to patties in a germ-free and energy-efficient way.

PRETZELS & CROISSANTS

Industry: Baked goods

Application: Even distribution / quality standard

In order to be able to guarantee an even distribution of lye on biscuits, Danish pastries or croissants, patented airknife drying systems are used here.

SALAMI

Industry: Meat products

Application: Clean, germ-free air

In this application, industrially produced salami sausages are cleaned automatically. By using HEPA filters, these are not only blown off in a way that saves energy, but is also germ-free.

POTATOES

Industry: Vegetables

Application: Clean, germ-free air

Potatoes are cleaned and transported to be packaged. Afterwards, water must be removed from the potatoes as much as possible. Existing compressed air units were replaced with patented air blades (HEPA class H14). The result was improved drying and a significant reduction of microbiological contamination including cost reduction.

APPLES

Industry: Fruit

Application: Cost-effective blow-off

Apples are transported while floating in a water basin and then sprayed with an additional “protective layer”. In order for this barrier to be distributed over the entire surface, the water drops must be blown off beforehand. This is achieved with the help of patented air blades, which are arranged across the belt from above and below.

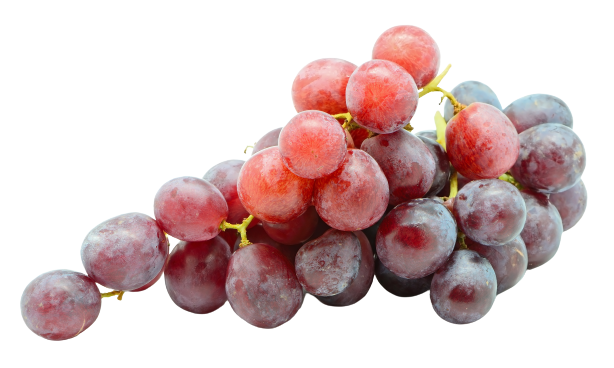

GRAPES

Industry: Fruit

Application: Cost-effective blow-off

After the washing process, the grapes are transported on a conveyor belt. A cost-efficient drying system can be easily assembled and installed using an assembly kit.

Packaged products

POUCHES | STANDING BAG

Industry: Pet food / fruit curd

Application: Drying before being packaged in a cardboard box

The product is filled, sealed and dried after pasteurization by means of blowing off with air blades and nozzles (standing floor) and packed in cardboard trays (to prevent softening).

CANNED GOODS

Industry: Food / Pet food

Application: Complete can drying (lid / side surface / base)

The bottom of the can is dried after pasteurization, turned over and the sides and the lid are blown off before dating.

- Before being packaged in cardboard trays (to prevent softening)

- Before foiling (to prevent condensation, which leads to corrosion).

SOFT CARDBOARD

Industry: Dairy / Foodstuffs

Application: Blow-off Dating range

After filling up soft cardboard, the top is dried before dating.

When making sauces, complete drying may be necessary before the final inspection weighing.

GLASSES

Industry: Dairy / Foodstuffs

Application: Removing condensation

Drying within the cooling circuit before labelling with self-adhesive label.

MULTI-PACKAGING

Industry: Food / Pet food

Application: Drying before being packaged

After pasteurization (autoclaving), drying is integrated into specifically developed transport technology.

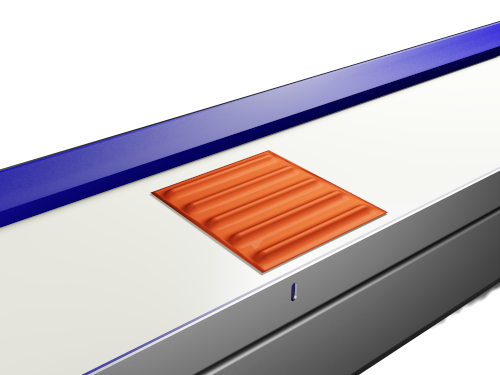

THERMOFORMING PACKAGING| SHRINK-WRAPPING

Industry: Foodstuffs

Application: Drying before being packaged / labelling

The product is dried after pasteurization (autoclaving). The specifically developed transport technology is used to dry the underside as well.

For mobile and large-area blow-off applications, belt cleaning for example.

The GESETE FLEX | line is a mobile blow-off system with efficient air blade and blower technology. The system can be positioned at the respective place of use quickly, easily and flexibly.

Application examples: Large-area drying or cleaning of product belts, removing particles and dust, even distribution of coatings, blowing off excess product, reducing cleaning times, making cleaning intervals longer, longer production time due to shorter cleaning cycles for belt cleaning.

We care about your energy

Do you have questions or would you like to find out more?