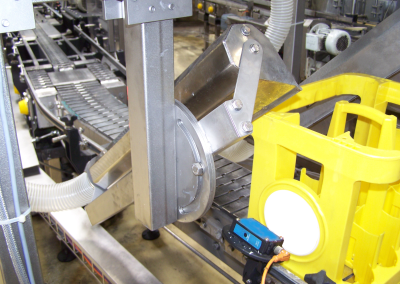

Blow-off can bottom and dating area

1:1 replacement of compressed air

Typical applications

- Removes 99.995% of residual water at the bottom

- Blows off residual water before dating (avoiding illegible print)

- Avoiding stress corrosion in the cover area/tear flap by blowing off residual water

- Replacing expensive compressed air

We care about your energy

Do you have questions or would you like to find out more?