Complete bottle drying

Highest quality to meet the highest demands

Typical applications

- Adhesive water removal prior to labeling of any kind.

- Targeted removal of product residues

- Thread and neck finish blow-offs (HEPA filtered)

- Drying of any type of closure (crown cork, screw cap, etc.)

- Drying before leak testing

- Drying of empty bottles before inspection

- Avoiding water carry-over in production and into the warehouse

- Drying before packaging in cardboard

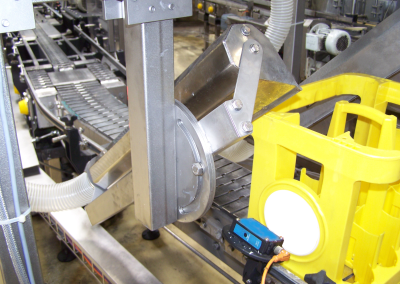

Projects GLASS BOTTLES

We care about your energy

Do you have questions or would you like to find out more?